Pottery for Sale in London

To view my homemade pottery for sale

here in London, England, (some

were made by my two boys below), scroll to the right on this page and at this point. You

can click on and hold the scroll square/box in the scroll bar for faster scrolling.

You can press F11 to view the webpage across the entire screen, since many of the pictures

are rather large.

Above each picture you will see a number, which you can refer to when telling me which of

my pottery you like. If you like any of them, please email me to [email protected], or contact me through this form if you want to avoid the

spamguard.

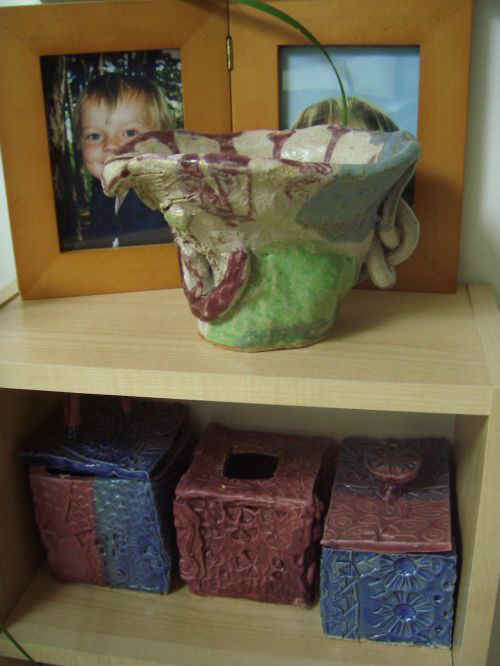

These are my lovely two boys. :o)

|

1

|

2

|

2

|

3

|

3

|

|

4

|

5

|

|

6

|

7

|

8

|

9

|

10

|

11

|

12

|

13

|

14

|

15

|

16

|

17

|

18

|

19

|

20

|

21

|

22

|

23

|

24

|

25

|

26

|

27

|

28

|

29

|

30

|

31

|

32

|

33

|

34

|

35

|

36

|

37

|

38

|

39

|

40

|

41

|

42

|

44

|

43

|

44

|

45

|

46

|

47

|

48

|

49

|

50

|

51

|

52

|

53

|

54

|

55

|

|

|

|

(please email me for an appointment) Description:

Part time eye doctor with a passion for pottery, I put my heart into it and even

my lovely two boys help me once in a while. The address on the net is not accurate but

near where I live. Please email

Payment types: Postal Order, Check, Invoice, Cash, MasterCard, Visa,

Paypal

Categories: Retail Stores - Craft Supplies |

Site on google |

Simona's home made pottery

I started with pottery in the late 1980s, when I was in

highschool. I then went on to study medicine and became an eye doctor, but pottery for me has always

represented a healthy balance against my scientific career. An artistic outlet for me from

the nine to five grind. I enjoy creating things with my hands and I love the feel of wet clay oozing through my

fingers. I've been going to pottery class for three hours

every Thursday evening since I started until now. I've even got my kids involved in it and

they have adorned our house with many lovely pieces. One of the reasons I like going to

class is that I get to meet people, who have a similar passion for pottery but who have

very varied backgrounds. Of the various styles of pottery, I prefer hand building mine,

without the use of the wheel.

I prefer to make primarily functional pieces, such as garden pots, and I prefer stoneware clays and

glazes, as they produce more muted colours. Over the years I have amassed quite a

collection, giving many to friends, and filling up the shed until my kids refer to it as

"mummy's gallery". As an eye doctor I work three days a week so that I can spend

more time with my children, but if I can start to sell some of my growing collection, I

would enjoy spending more time making pottery, making a second career out of it. I have

many pieces which are not on this website, and I can make custom designed ones on

commission. Each of my pieces is painstakingly and lovingly created, highly original, and

I make them for pleasure rather than business. I'd love to find my pottery pieces in a

loving new home.

Information about Pottery

Pottery also includes ceramics,

earthenware, stoneware and porcelain, all of which are made in potteries.

Pottery is made from clay, mostly formed by the hand while it is still soft and wet, and

then heated in a kiln at high

temperatures to change its material quality, making it hard. The clay itself varies from

region to region to produce pottery with varying characteristics. Furthermore, the clay

itself can be mixed with different minerals to create different effects.

History of Pottery

The earliest known pottery was produced 25 to 29,000 years before Christ

in what is now modern day Czech

Republic (where I was born), of a figurine of a naked woman named Venus of Dolni

Vestonice . The earliest known pottery vessels were made in Japan in 10,500 BC. Pottery

was independently discovered in North Africa around 10,000 BC, and in South America around

the seventh millennium before Christ.

Some time between 4,000 and 6,500 BC, the invention of the potter’s wheel in

Mesopotamia, what is now modern day Iraq and the starting point of civilisation,

revolutionised the industry and helped feed the growing needs of the world’s first

cities.

In the early days, the pottery was heated in bonfires, or holes in the ground

covered with fuel, reaching temperatures of around 900 degrees Celsius.

Since designs are used to adorn pottery, and because pottery was invented and proves very

useful for storing food, liquids and other important commodities, it has become useful for

archaeologists in mapping out ancient cultures with their economic and social structures.

Especially since pottery tends to last much longer than other objects, such as wooden

tools and textiles. The thermoluminescence test then accurately identifies the exact date

of the pottery according to its last firing. Examining the iron materials in ancient

pottery shards has even revealed to scientists the exact state of the earth’s

magnetic field at the time of firing!

On a more local level, around the time of the first industrial revolution, taking place in

the United Kingdom, the city of Stoke

on Trent became known as The Potteries, where in 1785 its 200 pottery manufacturers

employed some twenty thousand labourers.

How to Make Pottery

When the clay has a specific dryness of around 75 to 85%, it becomes

“leather hard”, when it can be more easily moulded into shape and to which other

pieces can be added. Over the centuries of this trade many tools have been invented to aid

in the moulding

process, the most important of which is the potter’s wheel , where the spinning

mass of clay in the centre of the wheel can be formed into a vase or other similar vessel

with a consistent circumference. While some prefer the consistency and speed of the

potter’s wheel, arguing for the spontaneity of shape formed while the wheel spins,

others prefer to form shapes in the manner before the wheel was invented: from ground up

in a standing and stagnant position, arguing that this method produces more individually

unique pottery subject to a more robust imagination.

When using the wheel, it requires a certain amount of skill to first centre the

clay, then to open it by creating a hollow dip in the centre, then to create a floor

with a rounded bottom inside, then to throw the clay by drawing it upwards to

shape walls of even thickness, and finally to trim and turn it by removing

excess clay and refining its shape into its final form.

Although the wheel can speed up work and aid in creating more consistently similar shapes,

the general shapes themselves are more limited to ones with radial symmetry and a vertical

axis. But handles, lids and other extremities can be added at the end, or the produced

shape can itself be distorted by bulging and other methods, to create greater uniqueness.

Over time, machines have been invented to replace or aid the potter’s hand, speeding

up production further, but while simplifying any individuality, or removing unique traits.

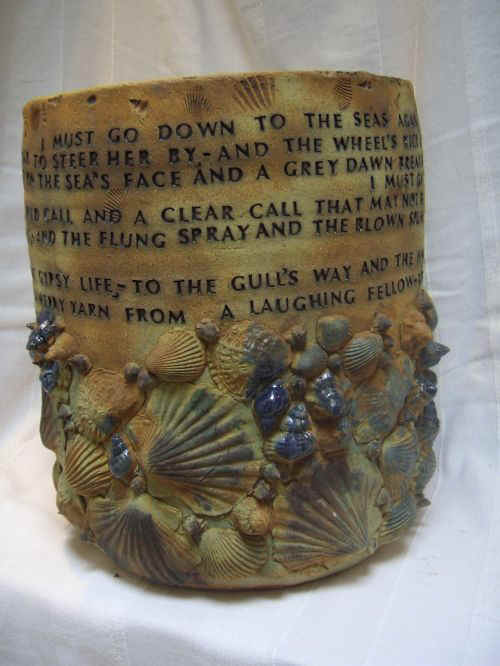

Once the final shape is complete, the pottery can be decorated by incising patterns on its

surface, embedding on it foreign objects (such as with seashells in my Item

12 or 18 above), and eventually glazing and colouring it in any

number of ways.

Prior to glazing,

additives such as sand can be mixed into the clay, creating particular textures once the

pottery is heated and glazed. Combustible particles can even be mixed in or pressed onto

the surface to produce different effects during heating.

Mixing different clays of different colours can also produce interesting results, referred

to as “agateware”,

after the quartz mineral agate which has bands or layers of different color blended

together. In this process, the potter is careful not to overmix the different clays so

that the individual colours are distinguishable, and the choice of clays is also important

as they must have similar thermal movement characteristics during the heating stage in the

kiln.

Prior to heating in the kiln, the pottery can also be finely polished, referred to as burnishing.

The next stage, still before heating, can be engobing, which is to add on a layer

over top of the pottery, often by dipping the entire shape into a bath, or by painting it

on the pottery’s surface - a method used since pre-historic times. This outer clay

slip is often high in silica, and can be incised with engravings to pierce through the new

surface, revealing colours of the clay beneath. A second clay slip of different colour can

be further added, and later incised, to produce patterns of different colour, much like

the procedure used when making

Easter eggs.

Another method of applying design to the surface is similar to lithography, whereby an

image or colour on a decorative design layer is applied to the surface using a backing

paper, printed onto the surface much like screen printing. Once the design has been

transferred, a protective layer is applied, which may include a low-melting glass.

After this, gold can be applied or painted on in various ways for extra fancy pottery.

And finally, we have the glazing stage, which coats the pottery with a protective,

colourful and decorative surface. Its colour and appearance often changes during heating,

and the sealed result protects the inner clay from destructive moisture or water.

Different minerals and application techniques can be used to produce different effects,

giving the pottery its final touch and personality.

Once the clay mould has been prepared, the object is then subjected to firing,

which is the process of heating the vessel at different temperatures to harden it, after

which it can be called pottery. Different materials require different temperatures, but

all firing is generally at or above 1000 degrees centigrade. There can be several stages

of firing, which fuse together different minerals, while regulating air intake into the

kiln can produce different degrees of oxidation of the clay and outer glaze.

Useful External Links about Pottery in London

http://londonpottersguild.org/offer/sales.htm

- Each spring and Christmas season, pottery lovers from around the region are drawn to the

London Potters Guild show and sale. Over 30 local potters participate in these sales,

selling both sculptural and functional pieces.

http://www.studiopottery.co.uk/html/events6.html

- calendar of events concerning pottery in the London, UK area.

http://www.studiopottery.co.uk/html/rgal-london.html

- list of gallery events from the same website.

http://www.si.edu/Encyclopedia_SI/nmah/Englishceramics.htm

- Information or research assistance regarding English from the Smithsonian Institution.

http://www.potsherd.uklinux.net/atlas/Ware/LEST

- Atlas and information of Roman pottery in the London-Essex area.

http://www.studio-pots.com/

- One of the few galleries in the UK exhibiting both contemporary and classical Studio

Ceramics.

http://www.potfest.co.uk/courses.htm

- links to various pottery courses in the UK.

Here are the links to the individual pages of my London pottery: